Typically, striping floors are done with either paint or floor tape. While both methods offer some pros and cons, ultimately it's up to you to decide on the method that's more suited for your particular needs. Here, we'll look at the good and bad of each method as well as offering some simple tips for your next project.

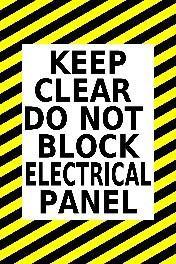

Paint is generally more permanent than tape. Although, there are some heavy duty tape options out there for more permanent designs on your manufacturing floor. Keep in mind that while painting the stripes are more everlasting, they often do require extra prep work. The paint may also give off a strong smell. Painting doesn't guarantee it from being worn out and recoating may be necessary to keep the stripes from dulling and wearing out. The repainting process is often just as tedious as the initial layer and requires a decent amount of prep work. If you're getting a contractor to do the job, then it'll be quite costly. When painting stripes on the floor, it's a good idea to start from the farthest end of your floor and work towards your door to prevent yourself from being painted in. Take it slow and mark carefully where you plan to paint since it's no easy task to remove it.

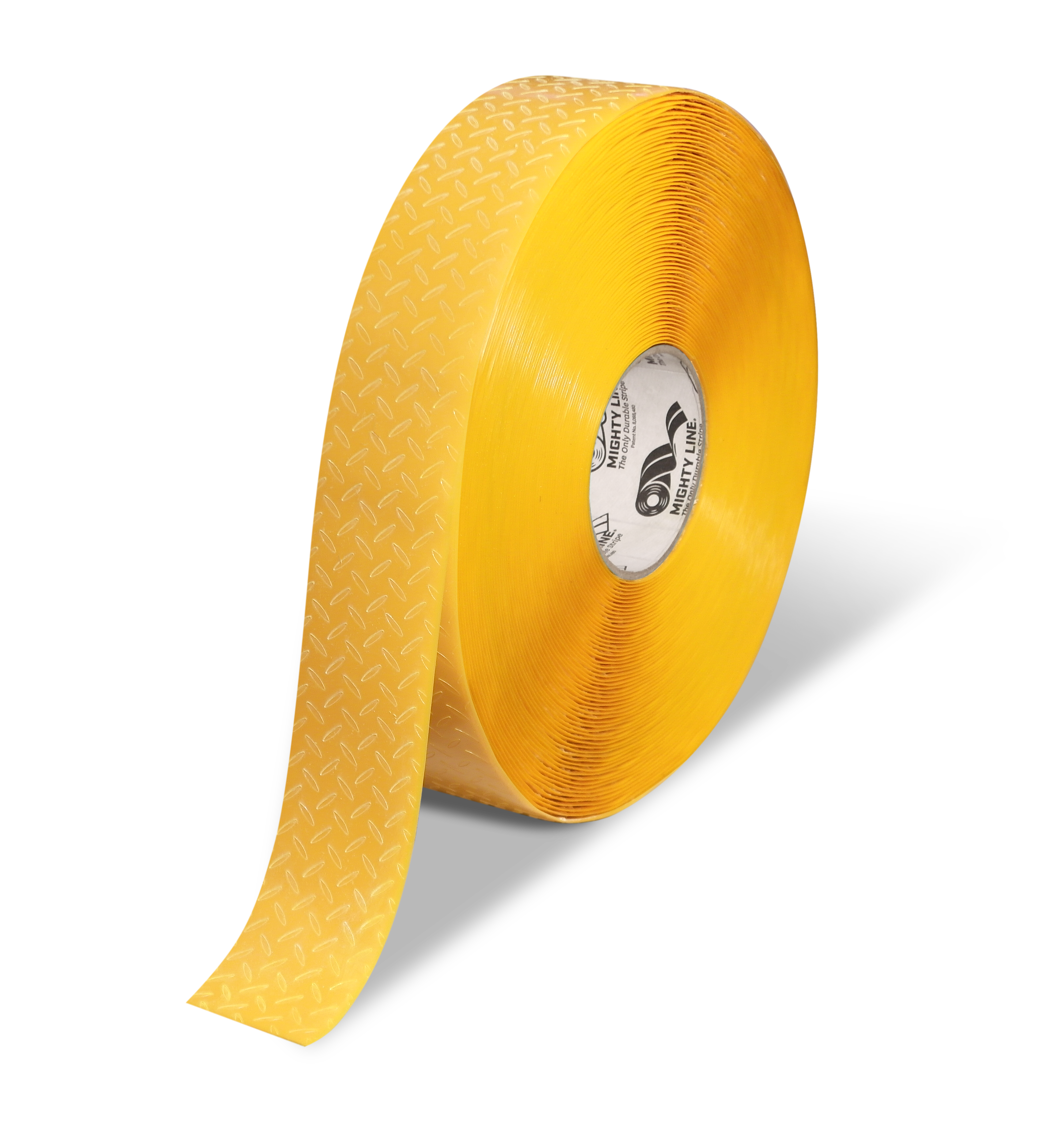

Floor tape is a great alternative to painting. Heavy duty tape offers the robustness of paint while making it much easier to work with. Typically, floor tape is easier to remove and easier to apply. When looking for high quality tape, search for extruded tape and not die cut. These tapes feature bevelled edges and a recessed adhesive system, they are stronger so they last longer and are also easier to remove if you ever decide to redo the floor design, they are also especially designed to withstand pushing and pulling of pallets and other items on the manufacturing plant floor.