When choosing the methodology for creating your new floor markings, there are a lot of options to weigh. Going with industrial tape over permanently painting will save you a lot of time and money in the long run. Another point to consider is the option of anti-skid tape, which may be a better choice for industrial warehouses with more slippery floors.

Whichever way you go, marking your industrial warehouse and shop floors clearly is essential to maintaining the reputation of your business and keep you from getting fined by OSHA.

Per the OSHA guidelines, there are specific colors to designate different safety codes. These codes will make it easier for employees and customers to navigate safely in your industrial space. Yellow – Caution! This is particularly important in walkways and aisles that have more possibilities for falling object and trip-and-fall hazards.

Yellow – Caution! This is particularly important in walkways and aisles that have more possibilities for falling object and trip-and-fall hazards.![]() Red – Danger! Stop! This color is meant to highlight fire protection equipment, like sprinklers and extinguishers. It is also used to designate actual stop signs for areas that are off limits to unauthorized individuals.

Red – Danger! Stop! This color is meant to highlight fire protection equipment, like sprinklers and extinguishers. It is also used to designate actual stop signs for areas that are off limits to unauthorized individuals.![]() Orange – Warning! More often used to mark energized machinery and other energized equipment, to warn against the possibility of electric shock.

Orange – Warning! More often used to mark energized machinery and other energized equipment, to warn against the possibility of electric shock.![]() Green – Safe! Go! First aid supplies, safety information and equipment, and emergency eye wash stations are all marked with the color green. The human eye already associates green with safety, so this is an easy connection for people to make naturally.

Green – Safe! Go! First aid supplies, safety information and equipment, and emergency eye wash stations are all marked with the color green. The human eye already associates green with safety, so this is an easy connection for people to make naturally.![]() Blue – Information! The signage which warns against moving equipment or equipment under repair is marked with blue. This will indicate to employees and customers when to look out for important information that needs their attention to proceed safely.

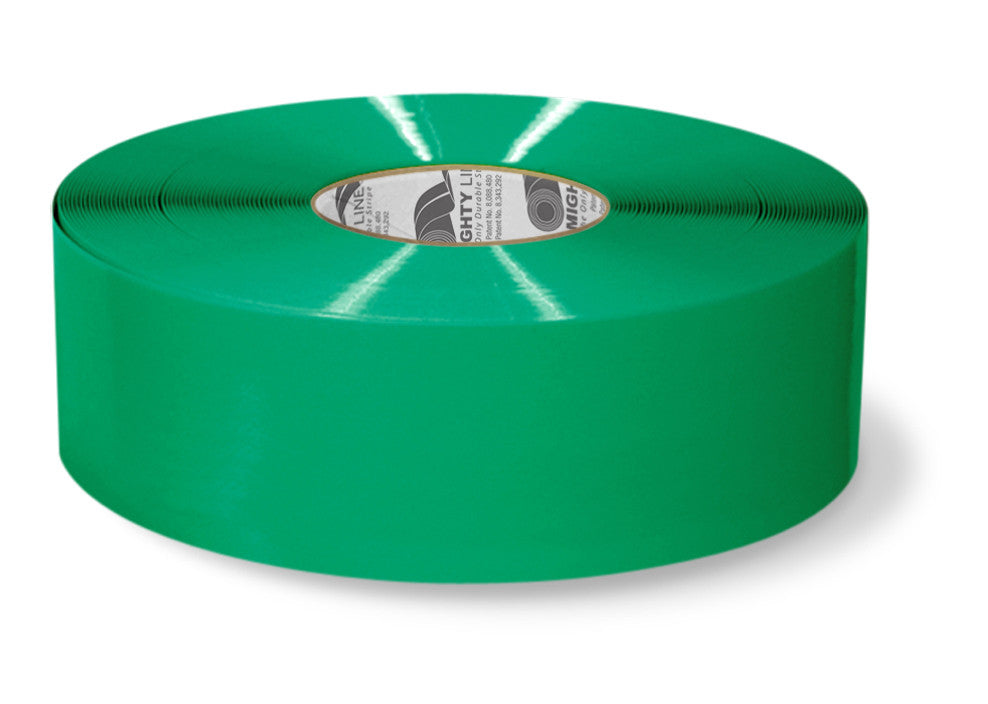

Blue – Information! The signage which warns against moving equipment or equipment under repair is marked with blue. This will indicate to employees and customers when to look out for important information that needs their attention to proceed safely. Stripes/Two Contrasting Colors – Attention! This technique is used to bring attention to areas with potential hazards, such as electrical panels and dead ends. Hazardous materials are also marked with striping colors.

Stripes/Two Contrasting Colors – Attention! This technique is used to bring attention to areas with potential hazards, such as electrical panels and dead ends. Hazardous materials are also marked with striping colors.